As a leading expert in the automotive industry, I am excited to introduce you to lsr cars – a groundbreaking innovation that is set to transform the way we drive. In this article, we will explore how lsr cars are changing the game and revolutionizing transportation as we know it.

The Advantages of LSR Cars

LSR (Liquid Silicone Rubber) cars offer numerous advantages over traditional vehicles. Firstly, they are incredibly lightweight yet durable, resulting in improved fuel efficiency and reduced emissions. Additionally, LSR cars have superior thermal stability and can withstand extreme temperatures without compromising performance or safety.

Furthermore, these innovative vehicles boast exceptional noise reduction capabilities due to their advanced insulation properties. This ensures a quieter and more comfortable driving experience for passengers. With their sleek design and cutting-edge technology integration, LSR cars are truly setting new standards in automotive engineering.

JVTECH: Pioneering LSR Car Manufacturing

A key player in the development of LSR cars is JVTECH – an industry-leading company specializing in advanced manufacturing solutions for silicone-based products. Through extensive research and collaboration with top engineers and designers, JVTECH has successfully created state-of-the-art production processes tailored specifically for LSR car manufacturing.

JVTECH’s expertise lies not only in producing high-quality liquid silicone rubber components but also in optimizing production efficiency through automation technologies. By leveraging their cutting-edge facilities and expertise, JVTECH plays a crucial role in bringing affordable yet premium quality LSR cars to market on a large scale.

The Liquid Silicone Molding Process

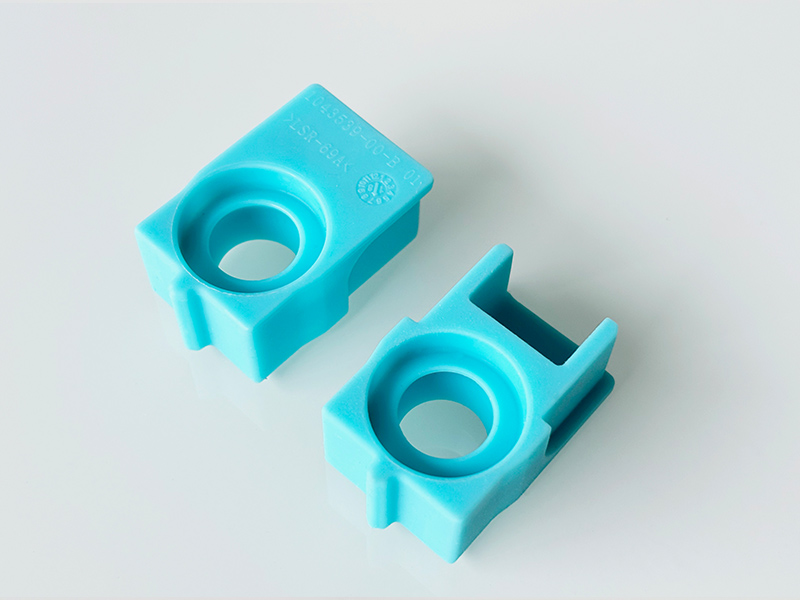

The heart of creating an LSR car lies within the liquid silicone molding process employed by manufacturers like JVTECH. This highly precise and efficient manufacturing technique involves injecting liquid silicone rubber into a mold, which is then cured to form the desired component.

One of the key advantages of this process is its ability to produce complex shapes with intricate details. The liquid silicone molding process allows for precise control over material distribution, resulting in consistent quality and performance across all LSR car components. Moreover, it enables manufacturers to achieve high production volumes while maintaining cost-effectiveness.

The Future of LSR Cars

LSR cars are undoubtedly paving the way for a greener and more sustainable future in transportation. With their lightweight construction, improved fuel efficiency, and reduced emissions, these vehicles offer an eco-friendly alternative without compromising on performance or safety.

As technology continues to advance and consumer demand for environmentally friendly options grows stronger, we can expect LSR cars to become increasingly prevalent on our roads. Their innovative design and superior capabilities make them an attractive choice for both individual drivers and fleet operators alike.

In conclusion, LSR cars are revolutionizing the automotive industry by offering numerous advantages such as lightweight construction, improved fuel efficiency, superior thermal stability, noise reduction capabilities, and advanced insulation properties. Companies like JVTECH play a crucial role in manufacturing these cutting-edge vehicles through their expertise in liquid silicone molding processes. As we look towards the future of transportation, LSR cars are set to drive us towards a greener and more sustainable world without compromising on style or performance.